The DamperControl variable is used to directly control the motor which is responsible for opening or closing the damper. The motor is controlled in the form of a floating type of control, where a specific drive time is required for correct (full opening) control, allowing for full opening of the damper under load.

Due to the possibility of the transmitted signal diverging from the actual opening (e.g., in the event of jamming, blocking, etc.), a calibrated mechanism is used, which involves a calibration process for the duration of the motor's drive time. This function is always performed after the power supply voltage fails and returns, and cyclically, e.g. every day at midnight.

The priority signal is the damper operating mode resulting from, among others, the balancing or testing procedure. In case of the version with a configured series fan, starting the fan is preceded by closing the damper waiting a specific time after the fan starts, and then opening it again.

In systems without the reheater, the damper is used as a heating source (requires the discharge air temperature sensor). In systems with the reheater, it is used as one of the heating stages (by default, as the second stage).

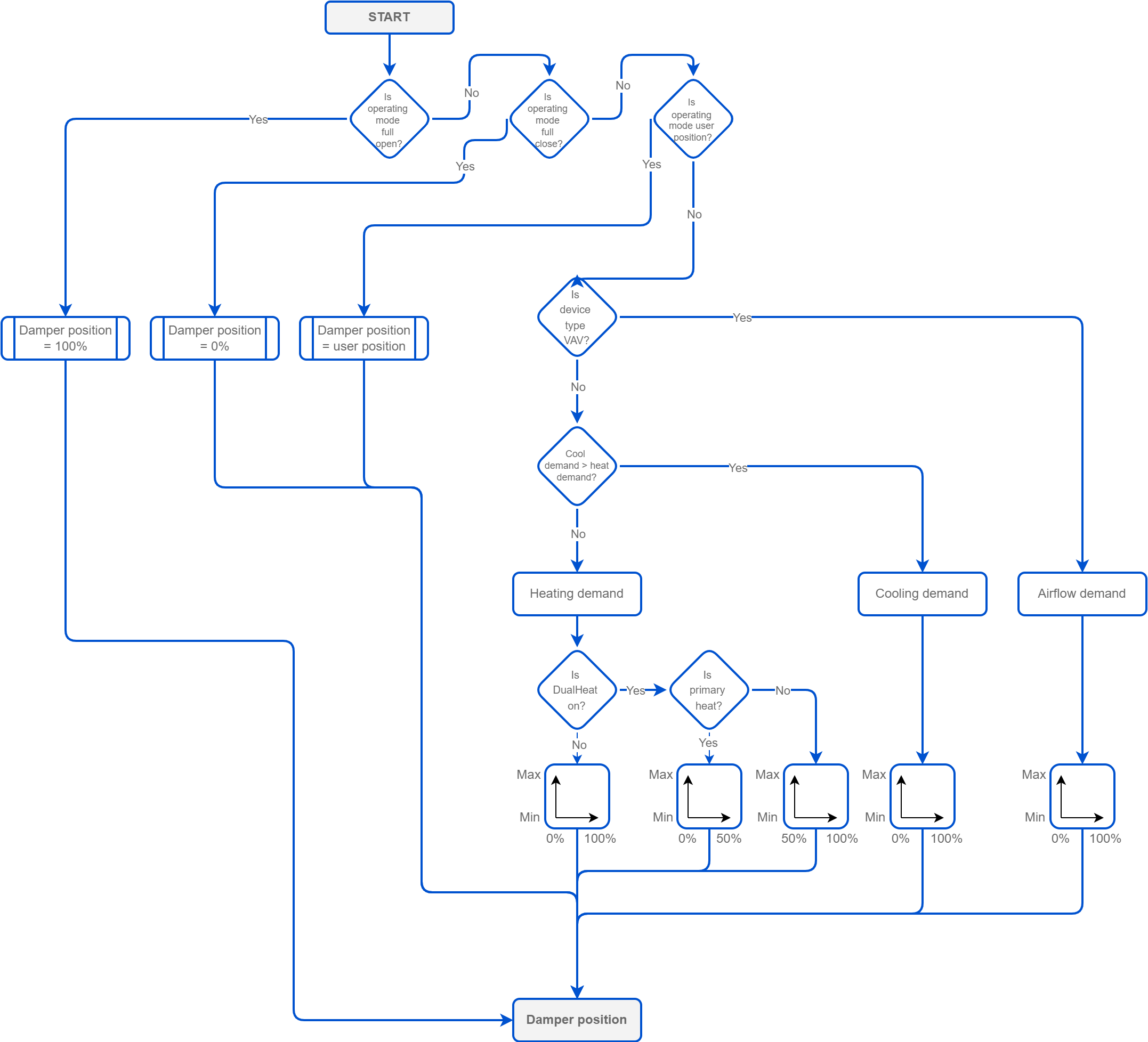

Damper control in the VAV application depends on the type of device selected in the DeviceType variable (DamperControl folder of the VAV application):

-

VAV (variable air volume system): damper control based on airflow demand (pressure independent),

-

VVT (variable volume and temperature): damper control based directly on cooling or heating demand (pressure dependent).

Damper control is carried out in the range defined by the MinDamperPosition and MaxDamperPosition variables, scaling the corresponding demands.

For the correct operation of the damper, the correct transition time for a full cycle – from fully closed to fully open – must be set in the DamperDriveTime variable (by default, 90 s) and the correct direction of damper operation must be set in the DirectionDirection variable as CW (clockwise) or CCW (counterclockwise).

Warning!

Changing the DamperDriveTime without a valid reason is strongly not recommended.

The DamperPosition variable returns the actual value of the damper opening, and the DamperControl variable returns its control.

The Damper Command variable, accessible from the Control Point VAV panel and iSMA Configurator, is mainly used to perform balancing and force testing of the set airflow. It allows to force the setting of the set airflow as maximum flow (for cooling), minimum flow (for cooling), as well as any airflow set in the UserSetAirFlow variable.

Damper Operating Modes

The damper can be configured to work in the following operating modes:

-

Auto: the damper is controlled according to the airflow control loop output (for VAV device type) or temperature control loops (for VVT device type),

-

Full Open: the damper control is forced to 100% open position,

-

Full Close: the damper control is forced to 0% open position (closed), even when the MinDamperPosition value is higher than 0%,

-

User Position: the damper control is forced to the user set position (the UserSetPosition variable),

-

Min Flow: the damper control is forced to fit the set minimum airflow (set in the the MinOccCoolAirflowSetpoint),

-

Max Flow: the damper control is forced to fit the set maximum airflow (set in the the MaxOccCoolAirflowSetpoint),

-

User Flow: the damper control is forced to fit the set user airflow (set in the UserSetAirflow),

-

Calibrate: forces the damper calibration (the damper goes to 100%, then to 0%, and goes back to the control loop output).

Initial Position

The Initial Position function is an auto-synchronization of the actuator, which allows for maintaining proper airflow parameters. In the process, the damper goes to 0% and goes back to the control loop output. It is performed each first day of the month, on the time calculated by the formula:

Calibration time = 00:00 + (serial number MOD 100)

This way helps to avoid the situation when all controllers perform the process at one moment, compromising the stability of the system.

DamperResponse

In case of significant fluctuations of airflow demand (resulting from the respective control loop), it is possible to mitigate the changes of value using the DamperResponse variable. It allows to enforce the change of value on the DamperControl component if the change of output demand is higher than set in the DamperResponse In16 slot (by default, 2%). It means that the DamperControl output will change only if the heating/cooling or airflow demand changes more than 2%.

DualHeat

The DualHeat function for damper allows to meet energy efficiency requirements by allowing to select between two modes of heating, primary or secondary. The damper is then controlled according to the setting of the HeatDamperPriority variable. The primary and secondary mode of heating work depending on the type of device:

-

VVT:

-

primary mode: the damper is controlled in a full range of 0-100% at the corresponding heating demand from 0-50%,

-

secondary mode: the damper is controlled in a full range of 0-100% at the corresponding heating demand from 50-100%;

-

-

VAV:

-

primary mode: the damper is controlled in a full range of 0-100% at the corresponding airflow for heating demand from 0-50%,

-

secondary mode: the damper is controlled in a full range of 0-100% at the corresponding airflow for heating demand from 50-100%.

-