General Functionalities

This chapter describes the user interface of the MVE-2-RS RS485 Configurator, which is the most advanced of the 2 available tools. In the user interface of the USB configuration tool, the Info tab does not include the functionality to show the charts, and it is not possible to set the BMS command signal but is possible to use the USB Configuration Tool in the offline mode (simulator).

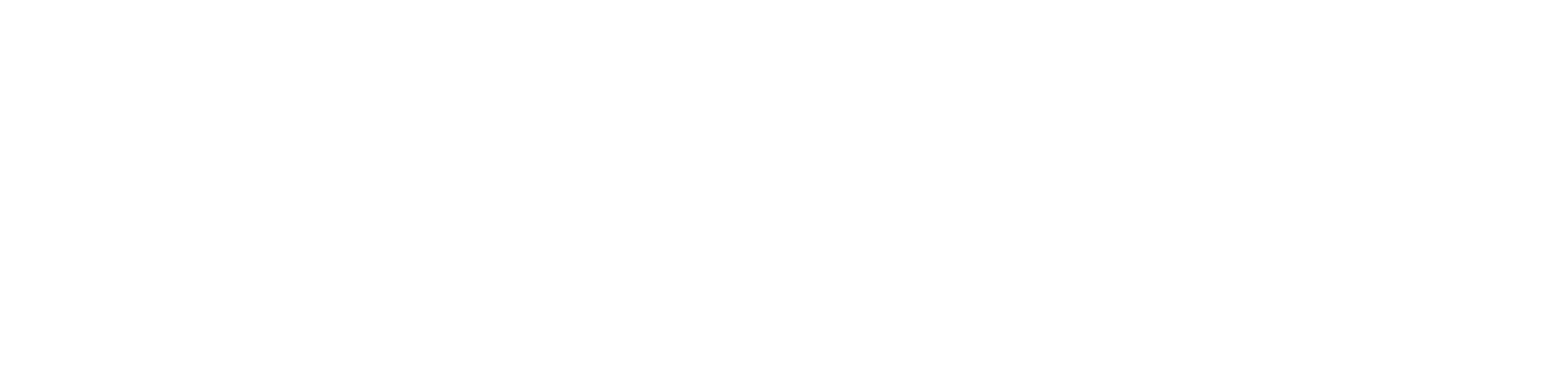

Opening the application, the following user interface will be displayed:

User interface at the startup

To enable the tabs, it is necessary to select the COM connected to the USB-RS485 converter and click the toggle button with the DISCONNECTED label. If the connection is successful, all tabs will be enabled. To list all COM ports available, click the COM port label.

The user interface allows the following functionalities:

-

Reading the main characteristics of the actuator and show real-time graphics (Info tab);

-

Configuring the actuator (Configuration tab);

-

Checking the actuator's status and its anomalies (Diagnostic tab);

-

Setting the Modbus parameters to connect to the actuator with the Modbus master (not available in the USB version);

-

Download the Firmware (FW Upgrade tab);

-

Uploading a configuration file or download the set parameters in a configuration file;

-

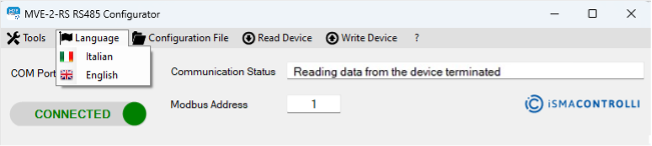

Selecting the language (Italian or English).

When any of the tabs is selected, all parameters shown in the page will be refreshed.

WARNING!

To read a parameter inside the tab, it is necessary to click the corresponding label.

To write a parameter inside a textbox, it is required to press Enter after a new value is entered or after selecting an item from a dropdown menu

To write a parameter inside a textbox, it is required to press Enter after a new value is entered or after selecting an item from a dropdown menu.

Dropdown Menu

The main window at the top shows the following dropdown menu:

Dropdown menu

-

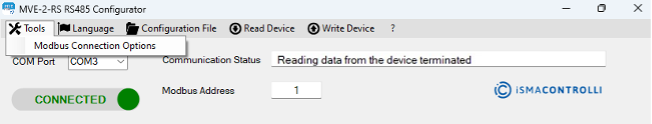

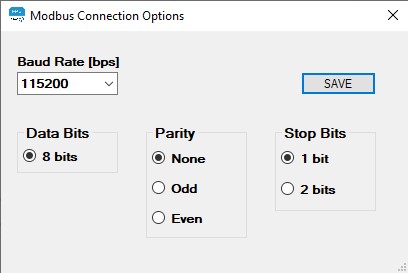

Tools: allows to define the Modbus connection options related to the iSMA-B-CVT-RS485 converter. If the user intends to change the Modbus connection options, the parameters have to be changed before clicking the toggle button to connect to the MVE-2-RS RS485 Configurator:

Tools menu

Modbus connection options

-

Language: allows to choose a language: Italian or English.

Language menu

-

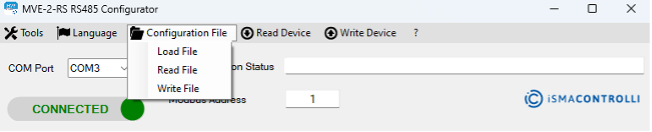

File Configuration: allows to:

-

Load File: load a .csv file with actuator parameters and send them to the actuator;

-

Read File: load a .csv file to show values on the tabs of the Configuration Tool without sending them to the actuator;

-

Write File: save a .csv file with the parameters set on the Configuration Tool.

-

Note: Only writable parameters will be saved in the .csv file.

File configuration menu

-

Read Device: allows to update the values in all tabs of the Configuration Tool;

-

Write Device: allows to write all configuration parameters into the actuator;

-

?: allows to read the software version of the Configuration Tool.

Other Functions

The following other items are shown:

-

CONNECT/DISCONNECT toggle button: connects/disconnects the RS485 Configuration Tool. In the MVE-2-RS USB Configuration Tool, the toggle button enables/disables the connection with the actuator via USB. In the MVE-2-RS USB Configuration Tool, the offline mode is available. The offline mode allows the user to use the Configuration Tool without the need of a real actuator connected to the USB of the PC. Offline mode is not available in the MVE-2-RS RS485 Configuration Tool.

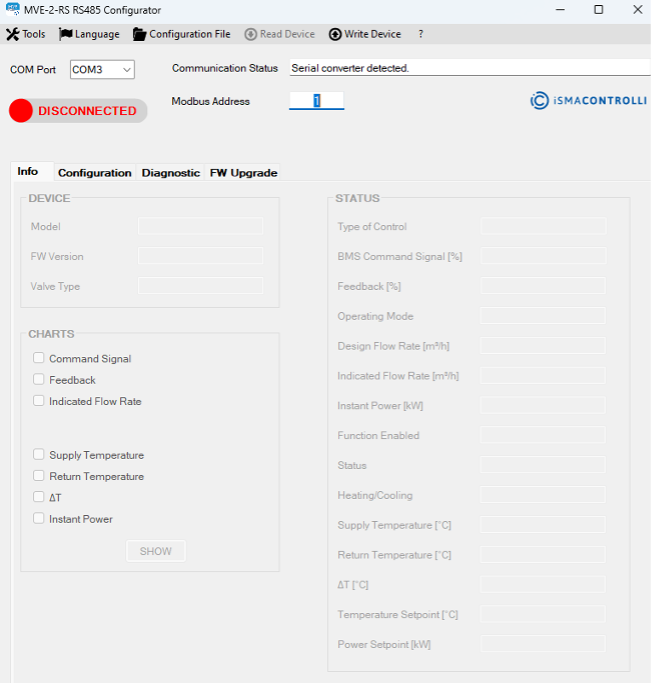

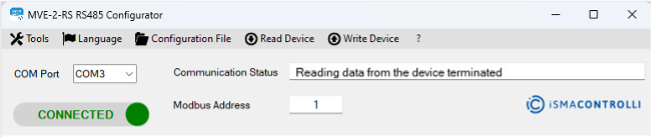

When the application starts, the toggle button is in the DISCONNECTED status; to initiate the communication between the actuator and master device, it is necessary to click the toggle button and the status of the button will change to CONNECTED.

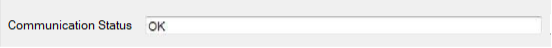

If the connection has been successful, the Communication Status label will state OK.

Communication Status shows the status of the USB communication

To disconnect the communication between the actuator and master device, click on the toggle button when it is in the CONNECTED status. If the disconnection has been successful, the DISCONNECTED notice will appear in the Communication Status field.

-

COM PORT (dropdown list): if the serial converter is already connected at startup, only the relative COM port is shown. Otherwise, click the COM PORT label above the dropdown menu; all the COM ports active on the PC will be listed. To select the correct COM port, which the USB-RS485 converter is connected to, follow the procedure in the Modbus Configuration section;

-

Modbus ADDRESS (textbox): shows the Modbus address of the device, to which the Configuration Tool will send all the command/operations. By default, the address is set to 1;

-

Communication STATUS (textbox): allows to view the status of the communication showing the outcome of the performed actions. If an action is successful, the OK status is shown.

Modbus RTU Configuration

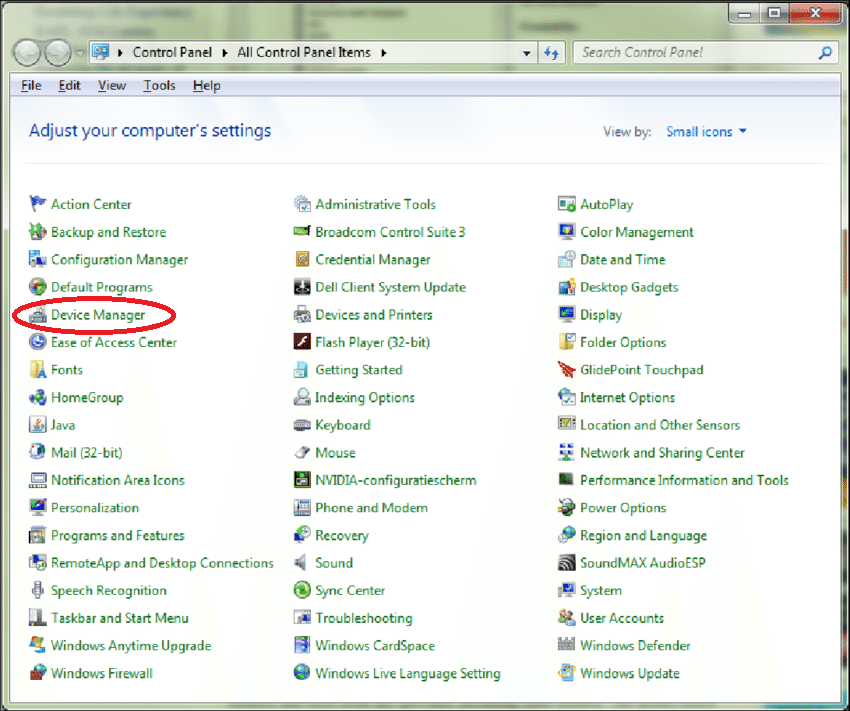

In the upper area of the main window, there is a dropdown list that displays the COM port currently in use by the PC. To identify the number of the serial port (COM Port), which the USB-RS485 converter is connected to, it is necessary to access the PC Control Panel and select the Device Manager:

Device Manager in the Windows Control Panel

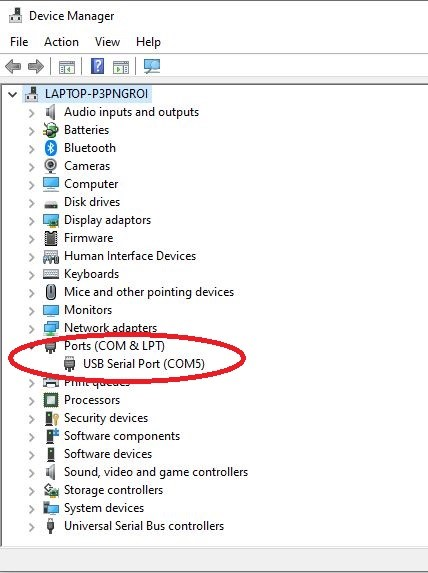

Select the Ports (COM and LPT) field to check the serial port number, which the serial converter is connected to (COM5 in the example below).

Device Manager Windows

Once the COM port has been selected, click the CONNECTED/DISCONNECTED toggle button, and verify if the Communications Status is OK.

As indicated in the previous section, the Modbus configuration parameters of the master can be selected through the dropdown menu: Tools → Modbus Connection Options. The changes of the Modbus connection parameters of the master must be done prior to clicking the connect toggle button.

By default, the communication parameters are:

-

baud rate 115200;

-

no parity bit;

-

1 stop bit.

Tabs

Info Tab

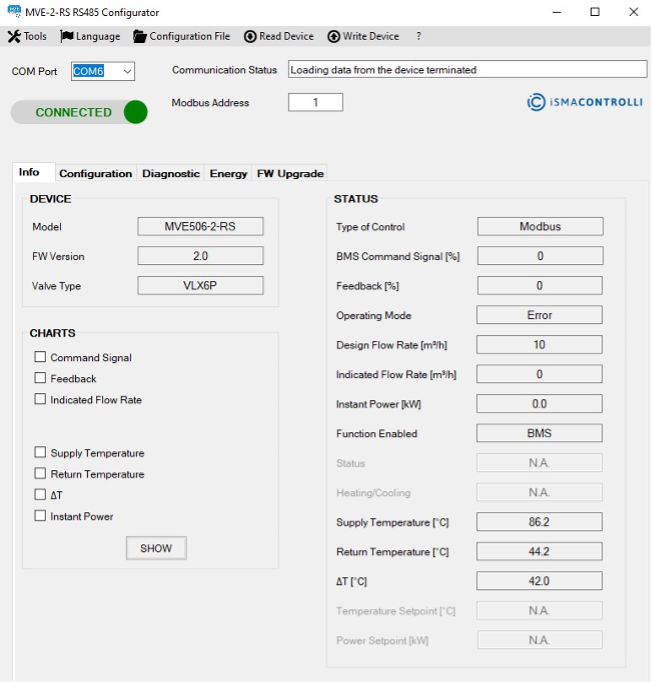

In this window, it is possible to read the main information about the actuator:

Info tab

-

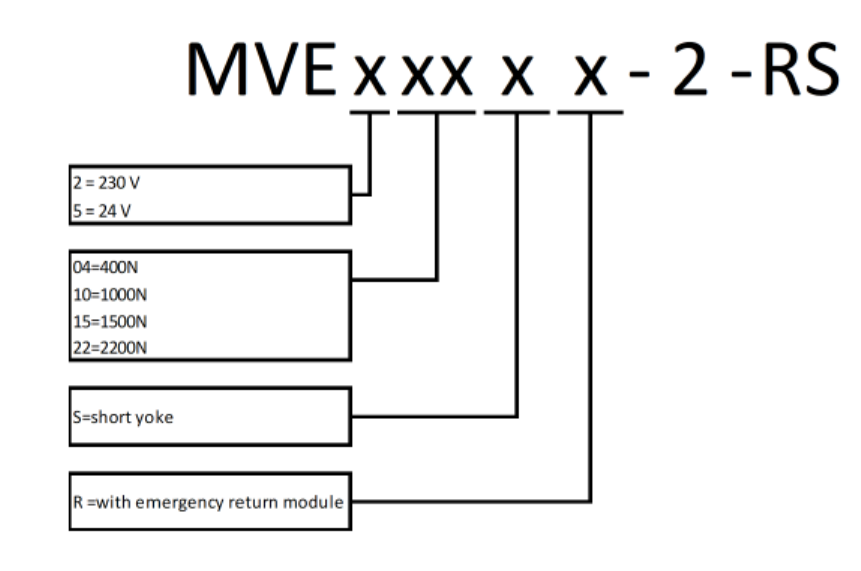

Model: represents the product part number. The alphanumeric code is composed as follows:

Example code

An example of the code is the following: MVE506-2-RS, which represents an MVE-2-RS model with 600 N of force, powered with 24 V AC Modbus/BACnet communication without emergency return.

The value cannot be changed in the Configuration Tool.

-

FW Version: : identifies the current version of the firmware installed on the actuator;

-

Valve Type: show the current valve connected to the actuator;

-

Type of Control: shows the command type for the actuator (the default value is 0-10 V, selectable by DIP switch);

-

BMS Command Signal [%]: shows the current Modbus command signal value (between 0-100%).

Note: It is a read-only value. The BMS command is set in the Configuration tab.

-

Feedback [%]: allows to identify the position of the actuator in the 0-100% range of the stroke;

-

Operating Mode: shows the operating status of the actuator, which can be one of the following:

-

Normal: the actuator is working following the command signal at its input; therefore, it is not in the initial positioning, calibration, emergency return, or manual override phases;

-

Initial positioning: the actuator is moving towards the initial position determined by the DIP 1 or, if the DIP switches are disabled, based on the action type value set in the Configuration tab;

-

Calibration: the actuator is calibrating the stroke;

-

Error: indicates that one or more errors have occurred; the details of the error are visible in the Errors section of the Diagnostics tab;

-

Manual override: shows that the manual command has been enabled; the actuator does not respond to the command signal until the manual override is disengaged and the initial positioning ends;

-

Fail-safe: shows that the actuator is in the emergency return phase due to the lack of power supply. This operative mode is available only for the emergency return models.

-

-

Design Flow Rate [m3/h]: this value (reading only) represents the maximum desired flow rate.

-

Indicated Flow Rate [m3/h]: this value (reading only) represents the flow rate calculated as a function of the valve position and the valve flow characteristic.

-

Instant Power [kW]: represent the current power. It is showed only if the selected valve is a PICV and if the temperature sensors work properly.

-

Function enabled: show which of the following function is enabled:BMS;Temperature Control;∆T limit;Temp Limit;Temp Limit;Power Control; Power Limit.

-

Status: shows if the limit function is active or not in real time;

-

Heating/Cooling: shows whether the heating or cooling control mode is active;

-

Supply Temperature [°C]: represents the temperature value, in °C, detected by the supply temperature sensor (it is the sensor connected to the T1 input of the terminal block). It is a read-only value;

Note: If a value of 500.0 is displayed, it means that the supply sensor (T1) is disconnected or faulty, and the relative TEMPERATURE SENSORS group box is disabled (the group box is gray). In case functions, which require that temperature sensors are enabled, this error condition is also highlighted in the Diagnostics tab. In case a temperature sensor anomaly occurs, all the related functionalities are disabled.

-

Return Temperature [°C]: represents the temperature value, in °C, detected by the sensor positioned at the valve outlet port (it is the sensor connected to the T2 input of the terminal block). It is a read-only value;

Note: If a value of 500.0 is displayed, it means that the return sensor (T2) is disconnected or faulty, and the relative TEMPERATURE SENSORS group box is disabled (the group box is gray). In case of functions which require that the temperature sensors are enabled, this error condition is also highlighted in the Diagnostics tab. In case a temperature sensor anomaly occurs, all the related functionalities are disabled.

-

∆T [°C]: shows a difference between the supply and return temperature value, in °C;

Note: If the temperature sensors have problems or are not connected, 500.0 is displayed.

-

Temperature Setpoint [°C]: shows a setpoint configured for the temperature control enabled function;

-

Power Setpoint [kW]: shows a setpoint configured for the power control enabled function;

-

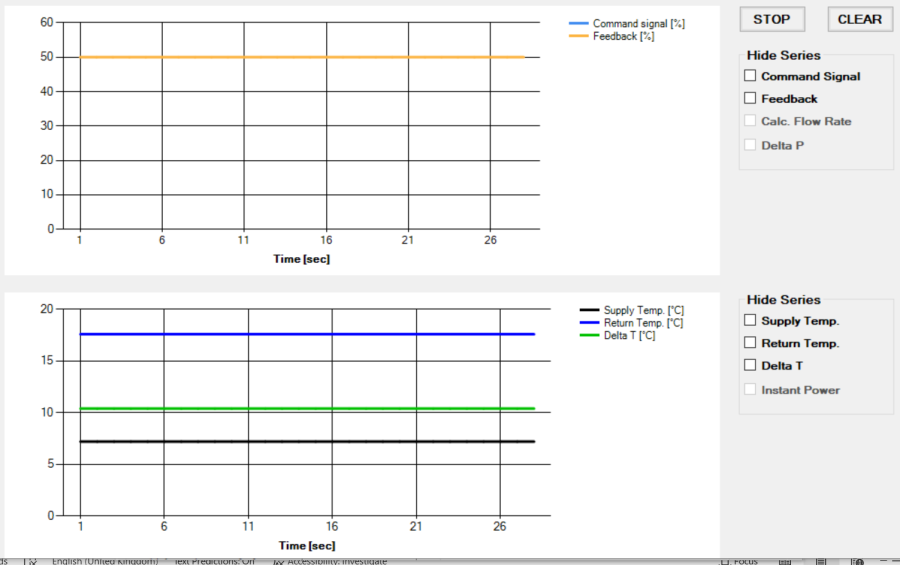

CHARTS: by checking the items listed in this section, it is possible to view the charts of the desired variables. The graphs are grouped into 2 types: the Control charts (command signal, feedback, indicated flow rate) and the Temperature and Power charts (supply temperature, return temperature, delta T, instant power). clicking the CHARTS button, a window will appear with selected charts. The 2 types of variables are represented on 2 different graphic areas (see the figure below).

WARNING! The CHARTS functionality is NOT available in the MVE-2-RS USB Configuration Tool.

The charts window

The window shows the 2 areas for the 2 types of charts described above. The charts displayed are those selected in the Info tab, and they are updated every second starting from the opening of the window in the specific chart area.

It is possible to stop updating charts and display them by clicking the STOP button, and resume updating by clicking the START button (the same button, therefore, allows to stop or restart the display). When updating is resumed, the first data displayed will be the current one and not the one at the time of the stop (therefore, the data will be lost during the time the chart stops).

It is possible to hide one or more plotted graphs from the display by marking checkboxes in the Hide series section (the series is hidden, but the acquired data continues to be stored anyway).

It is again possible to show the previously hidden graphs by removing the check mark from the specific box; as mentioned, the graphs will show a temporal continuity in the data even if they were hidden.

The CLEAR button allows to delete the graphs from the display area.

After 90 minutes the charts are no longer updated because the maximum number of data that can be displayed has been reached. A pop-up message warns the user and asks if the data should be saved to a file (.csv); if the action is confirmed with the Yes button, a window is opened for saving the file, and, once the name of the file is indicated, the charts in the two areas are deleted. By clicking the No button, the data are not saved to the file, and the charts will be deleted. By clicking, the START button, it is possible to restart the data display from the current instant.

Configuration Tab

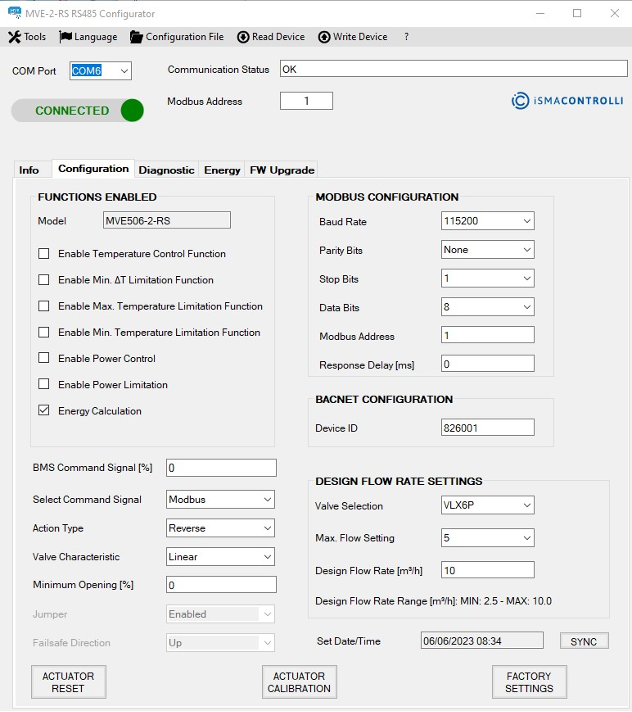

In this window, it is possible to set the following actuator's configuration parameters:

Configuration tab

-

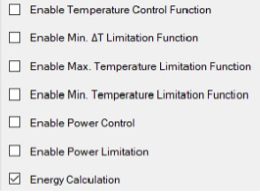

FUNCTIONS ENABLED: shows the available functions for the actuator model;

Selection of functions to enable

- Temperature Control Function: the function constantly overrides the control signal to maintain the set temperature or ΔT by closing or opening the valve;

- Min. ∆T Limitation Function: the actuator is controlled by the input signal (voltage or current control) or by the Modbus/BACnet command but, if the ∆T goes below the temperature limitation set (heating or cooling), the actuator overrides the command closing the valve;

-

Max. Temperature Limitation Function: the actuator is controlled by the input signal (voltage or current control) or by the Modbus/BACnet command but, if the temperature exceeds the temperature limitation set (heating or cooling), the actuator:

-

opens the valve in cooling,

-

closes the valve in heating;

-

-

Min Temperature Limitation Function: the actuator is controlled by the input signal (voltage or current control) or by the Modbus/BACnet command but, if the temperature goes below the temperature limitation set (heating or cooling), the actuator:

-

closes the valve in cooling,

-

opens the valve in heating;

-

- Power Control: the actuator calculates the thermal power transferred from the coil and control it. This function is enabled when the actuator is installed on a PICV valves (iC or custom) and both temperature sensors are installed on the MVE-2-RS.

- Power Limitation: the actuator limits the opening of the valve when the calculated power is greater than a Max Set value. This function is enabled when the actuator is installed on a PICV valves (iC or custom) and both temperature sensors are installed the MVE-2-RS.

- Energy Calculation: the actuator calculates the instantaneous thermal power and energy (heating\cooling) supplied by the controlled coil. This function is enabled when the actuator is installed on a PICV valves (iC or custom), both temperature sensors are connected to the MVE-2-RS and date and hour are synchronized.

-

BMS Command Signal [%]: allows to set the Modbus/BACnet command for positioning the actuator between 0-100% (0.1% step). To send the command to the actuator, press the Enter key on the keyboard;

-

Select Command Signal: allows to select the type of command signal for driving the actuator (by default set to 0-10 V, selected by DIP switches);

-

Action Type: if Modbus/BACnet is enabled, this menu allows to select the action type of the actuator (direct or reverse). To write the selected value into the actuator, press the Enter key on the keyboard;

-

Valve Characteristic: it is possible to select the characteristic of the valve: linear or equipercentage (EQP);

-

Minimum Opening [%]: represents the minimum opening valve (expressed as a percentage) necessary to ensure a minimum of flow in the system;

Note: to save a specific value into the actuator, it is required to press Enter key on the keyboard. To save all data, it is possible to click the Write Device option.

-

Jumper: allows to select if the emergency return direction is determined by the jumper on the emergency return board (enabled) or by the Modbus or by BACnet. This is enabled for the emergency models only;

-

Failsafe Direction: allows to select the emergency return direction (up or down) if the Enable Jumper function is disabled. This is enabled for the emergency models only;

-

MODBUS CONFIGURATION: allows to set the Modbus configuration parameters of the actuator, in particular:

Note: The factory settings of the actuator are: baud rate 115200, no parity bit, and 1 stop bit.

Note: To write the value in the actuator, press “Enter” on the keyboard after selecting the desired value.

-

BACNET CONFIGURATION: allows to configurate/read the BACnet Device ID.

-

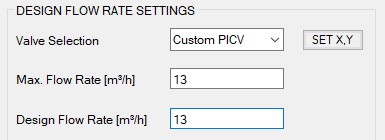

DESIGN FLOW RATE SETTING:

Custom PICV

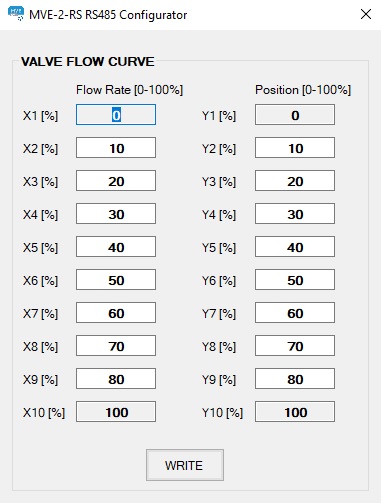

Pressing the button opens a window in which it is possible to write down the flow rate (X) and position (Y) percentage values of the valve characteristic curve. When the window opens, a reading of the flow rate and position values is taken;

Flow rate and position

-

Set Date/Time: when the tab Configuration is selected, the textbox displays automatically the current date and time of the PC are saved in the actuator. At the same time, the clock error displayed in the Diagnostics tab disappears. Each time the actuator turns off (the error condition is indicated in the Diagnostics tab), the date and time must be synchronized.

Note: By clicking on the Actuator Date/Time label, the date and time inside the actuator is read and displayed in the textbox.

-

Actuator Calibration: forces the calibration of the actuator stroke;

-

Actuator Reset: performs a software reset of the actuator;

-

Factory settings: restores factory values to the actuator reload. This action overwrites the configuration and data inside the actuator.

The variables in this window are read from the actuator and displayed when the Configuration tab is clicked from any tab or by clicking the Read Device item from the dropdown menu. It is also possible to invoke an instant reading of a textbox by clicking on the corresponding label.

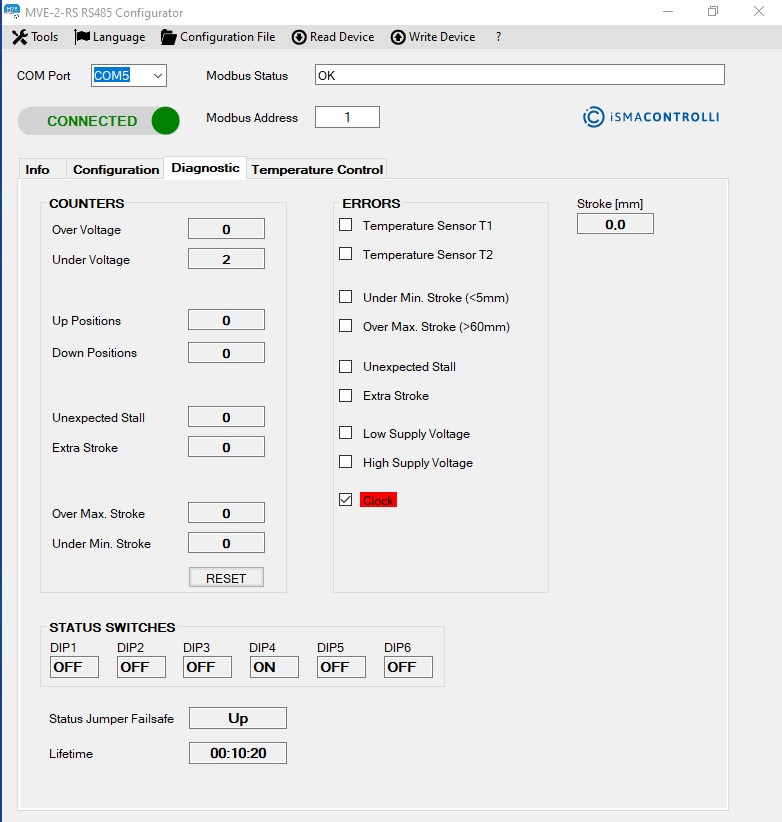

Diagnostic Tab

In this window, it is possible to view the status of the actuator and the occurrence of any anomalies:

Diagnostic tab

-

Stroke [mm]: shows the value of the actuator stroke calculated in mm during a calibration phase. It is a read-only value.

The COUNTERS section displays the number of events (mainly anomalies) that have occurred in the actuator. The events that can be logged are:

-

Over Voltage: shows how many high voltage supply anomalies have occurred;

-

Under Voltage: shows how many low voltage supply anomalies have occurred;

-

Up Positions: identifies the number of times that the actuator has been fully retracted;

-

Down Positions: identifies the number of times that the actuator has been fully extended;

-

Unexpected Stall: identifies an unexpected stall anomaly; this value represents the number of times that a stall has occurred within the stroke;

-

Extra Stroke: identifies an extra stroke anomaly; this value represents the number of times an extra stroke has occurred compared to the stroke calculated during the last calibration phase (out-of-range stroke);

-

Over Max. Stroke: shows how many stroke anomalies calculated by the actuator in the calibration phase (stroke greater than 60 mm) have occurred;

-

Under Min. Stroke: shows how many stroke anomalies calculated by the actuator in the calibration phase (stroke less than 5 mm) have occurred;

-

RESET: allows to reset all the counters (Over Voltage, Under Voltage, Up Positions, Down Positions, Unexpected Stall, Extra Stroke, Over Max. Voltage, Under Min. Voltage).

The ERRORS section shows the detectable actuator errors:

-

Temperature Sensor T1: the temperature sensor connected to the T1 terminal (supply temperature) has an anomaly (if temperature sensors are required for the enabled functions);

-

Temperature Sensor T2: the temperature sensor connected to the terminal indicated with T2 (return temperature) has an anomaly (if temperature sensors are required for the enabled functions);

-

Under Min. Stroke (<5mm): during the calibration phase, a stroke was calculated below the minimum allowed value;

-

Over Max. Stroke (>60mm): during the calibration phase, a stroke above the maximum allowed value was calculated;

-

Unexpected Stall: the actuator is in an unexpected stall condition in the stroke range;

-

Extra Stroke: the actuator is in an extra stroke condition; therefore, the actuator is in a position beyond the calculated stroke;

-

Low Supply Voltage: the power supply of the actuator is below the minimum allowed threshold (the performance of the actuator is not guaranteed);

-

High Supply Voltage: the power supply of the actuator is above the maximum allowed threshold (the performance of the actuator is not guaranteed);

-

Clock: indicates that the time and date have not been set in the actuator since the last time the actuator was switched on (it is necessary to enable the energy function and, consequently, to read the energy data). Synchronization is carried out in the Configuration tab as described in the specific paragraph.

Active errors are highlighted in red color.

The STATUS SWITCHES section allows to read the DIP switches configuration set on the actuator. The status of the switches is updated only after having engaged and disengaged manual override or after a reset command or after having power off/on the actuator.

-

Status Jumper Failsafe: shows the jumper status (up or down) to indicate if the jumper on the emergency return board is inserted or not (it determines the fail-safe direction). The Status jumper fail-safe is applicable only if the Jumper is set on Enabled).

-

Lifetime: shows how long the actuator has been switched on.

The variables present in this window are read when the “Diagnostic” tab is clicked from any tab or when the “Read Device” item from the dropdown menu is clicked.

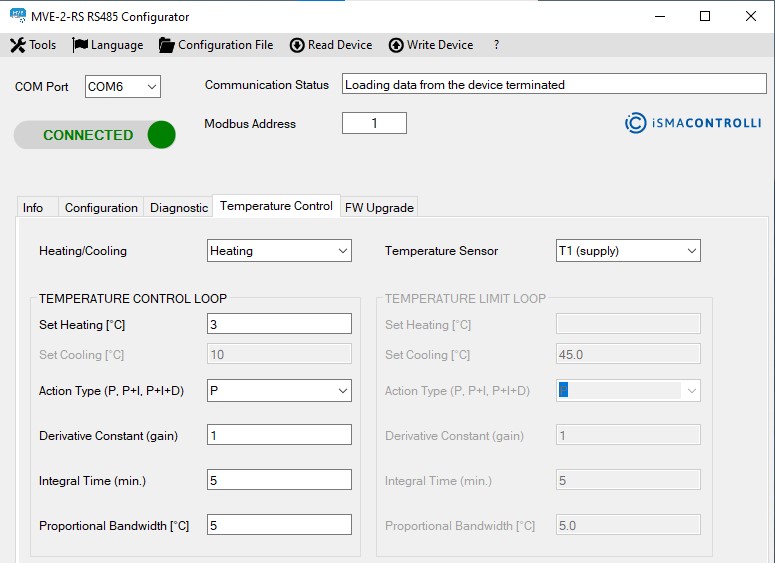

Temperature Control Tab

In this window, it is possible to configure and check the parameters of the temperature loop function.

This function is enabled only if the actuator is installed on a PICV (iC or custom) and both temperature sensors are correctly installed.

To save the set values, press the “Enter” key on the keyboard.

The 2 sections in this tab are enabled/disabled (gray color) based on the enabled function in the Configuration tab.

Temperature Control tab

-

Heating/Cooling/Automatic (ΔT): sets a cooling or heating or automatic (based on ΔT) mode;

-

Temperature Sensor: sets the temperature sensor (T1 supply, T2 return, or ΔT) to use in the selected temperature function.

The TEMPERATURE CONTROL /LIMIT LOOP section allows to set the parameters for the temperature control/limitations functions:

-

Set [°C]: represents the temperature setpoint value;

-

Action Type (P, P+I, P+I+D): represents the type of control of the system to be used to regulate the desiderate temperature. To write the selected value into the actuator, press the Enter key on the keyboard;

-

Derivative Constant (gain): represents the contribution of the derivative action;

-

Integral Time (min): defines the time within which the proportional action is proposed again;

-

Proportional Bandwidth ∆T [°C]: represents the temperature error value (error = current temperature value - setpoint temperature), beyond which the valve will be fully open;

To save the desired value it is necessary to press the “Enter” key in the keyboard. To save all data press “Write Device”.

Furthermore, it is possible to do an instantaneous read of the single information selecting on the specific label.

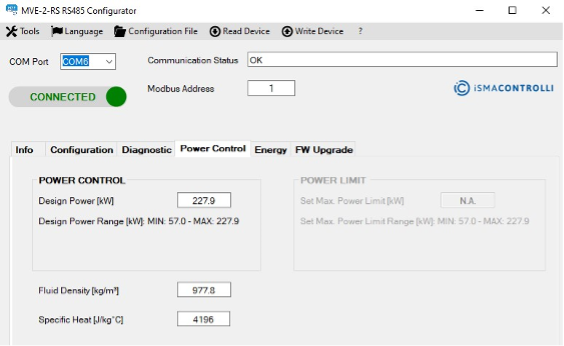

Power Control Tab

In this window, it is possible to configure and check the parameters of the Power Control function.

To save the set value of design power and max power limit, press the Enter key on the keyboard.

The 2 sections in this tab are enabled/disabled (gray color) based on the enabled function in the Configuration tab

Power Control Tab

The POWER CONTROL section allows to set the information for the power control function, in particular:

-

Design power [kW]: is the value of the power desired;

-

Design Power Range [kW]: it represents the maximum and the minimum value the Design Power can assume for the type of valve selected (for VLX6P it is 57.0-227.9);

The POWER LIMIT SECTION allows to set the information about the power limit value that the actuator can’t exceed, in particular:

-

Max. Power Limit [kW]: is the maximum power limit desired;

-

Max. Power Limit Range [kW]: it represents the maximum and the minimum value the Power can assume for the type of valve selected (for VLX6P it is 57.0-227.9);

Fluid density [Kg/m3]: this value indicates the density of the fluid (default setting water 977.8 Kg/m3);

Specific Heat [J/Kg °C]: this value indicates the specific heat of the fluid (default setting water 4196 J/Kg °C).

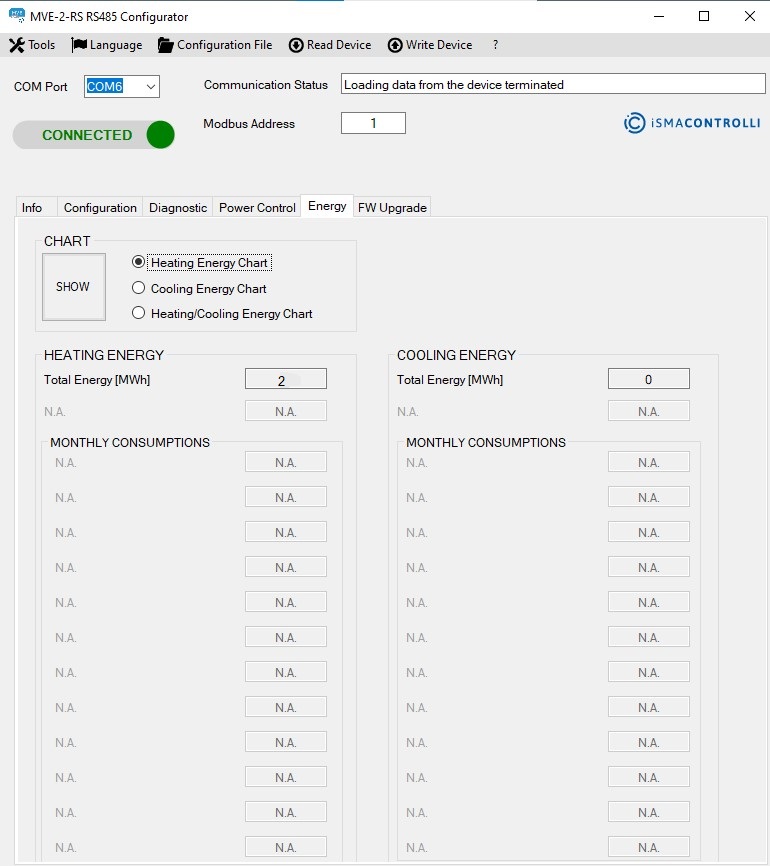

Energy Tab

In this window, it is possible to read the parameters of the Energy function and read the monthly consumption as histograms.

To save the set values, press the “Enter” key on the keyboard.

This function is enabled only if the actuator is installed on a PICV (iC or custom), both temperature sensors are correctly installed, and date and hour are synchronized.

The 2 sections in this tab are enabled/disabled (gray color) based on the enabled function in the Configuration tab.

Energy Tab

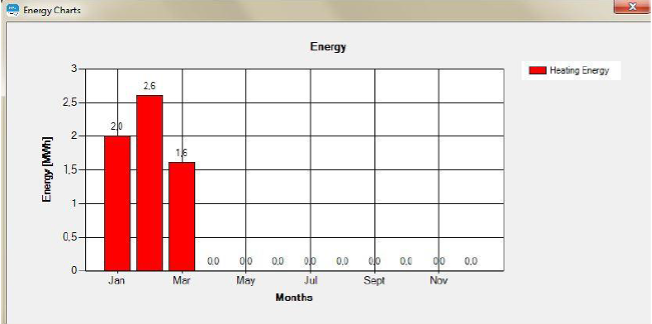

The CHART section allows to observe the histogram about the energy in the 12 months of the year regarding:

-

Heating Energy

-

Cooling Energy

-

Heating/Cooling Energy

Window of the histogram chart of the energy

The HEATING and COOLING ENERGY section shows:

-

Total Energy [MWh]: this value shows the total energy reading used until that moment;

-

Total Energy at 31/12/2023 [MWh]: this value shows the total energy reading at the end of the year;

-

MONTHLY CONSUMPTION [MWh]: in this section is reported the energy heating/cooling consumption for each month. If for a month there are no registered value, or they haven’t been calculated yet, then it will appear N/A.

The variables present in this window are read by the actuator and displayed when the “Energy” tab is pressed from any tab or by pressing the “Read Device” item from the drop-down menu.

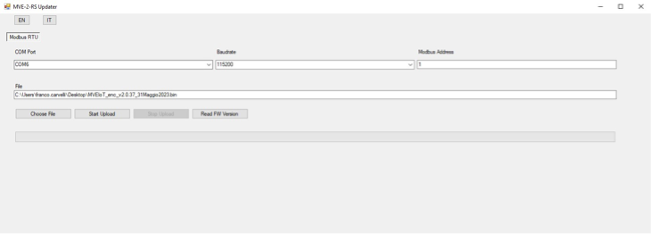

FW Upgrade Tab

After the selection of this tab the following window is shown:

FW upgrade window

In this window, it is possible to upgrade the actuator's firmware.

-

COM Port: displays all available COM port in the PC, it is necessary to select the one connected to the USB-RS485 converter;

-

Baudrate: allow to set the desired Baudrate (default 115200) through a dropdown menu; the baudrate has to be configurated with the same value of the actuator;

-

Modbus Address: allows to set the Modbus address of the actuator (default 1);

-

Choose File: allow to select the file to download;

-

Start Upload: start the download of the selected file;

-

Stop Upload: in case of problem this button allow to stop the download, it can be selected only when the download starts;

-

Read FW Version: Check the current FW version.