The calibration process is necessary in case when the time of slats opening is different than the default value stored in SLATS_OPENING_TIME register (1 second).

Calibration can be performed with monostable switches.

-

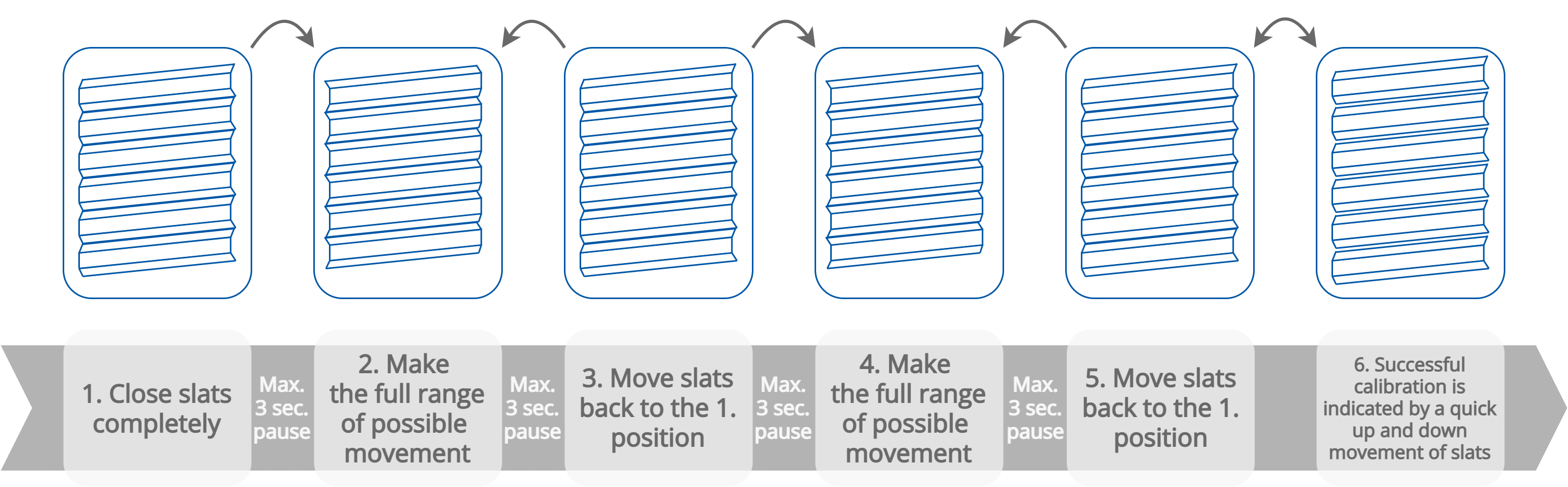

To begin the calibration process, the slats should be completely rotated down as presented on the figure (position 1).

-

From this position, the slats need to be completely rotated up (position 2 on the figure) by pressing the up switch shortly. Each press of the switch rotates the slats by a step proportional to the value stored in SLATS_OPENING_TIME.

-

The slats need to be rotated down back to position 1.

-

Points no. 2 and 3 need to be repeated.

Conditions necessary for the calibration to succeed:

-

Number of up/down steps to rotate the slats completely must be equal.

-

Number of up/down steps to rotate the slats completely must be greater than 5 and lower than 15.

-

Each opening/closing movement has to be initiated within 3 seconds after stopping the previous one.

-

Each rotation movement has to be initiated within 3 seconds after stopping the previous one.

-

The SLATS_NUMBER_OF_STEPS register needs to be set at the default value of 10 steps.

If the above conditions are met, the new opening time value is calculated by multiplying the old SLATS_OPENING_TIME by the number of opening / closing steps used in calibration and then dividing it by 10.

Example: SLATS_OPENING_TIME value is 1000 ms. Twelve steps are needed to completely rotate the slats in the calibration process. The new value stored in the register is: (1000 ms * 12) / 10, which equals 1200 ms.

Slats calibration procedure