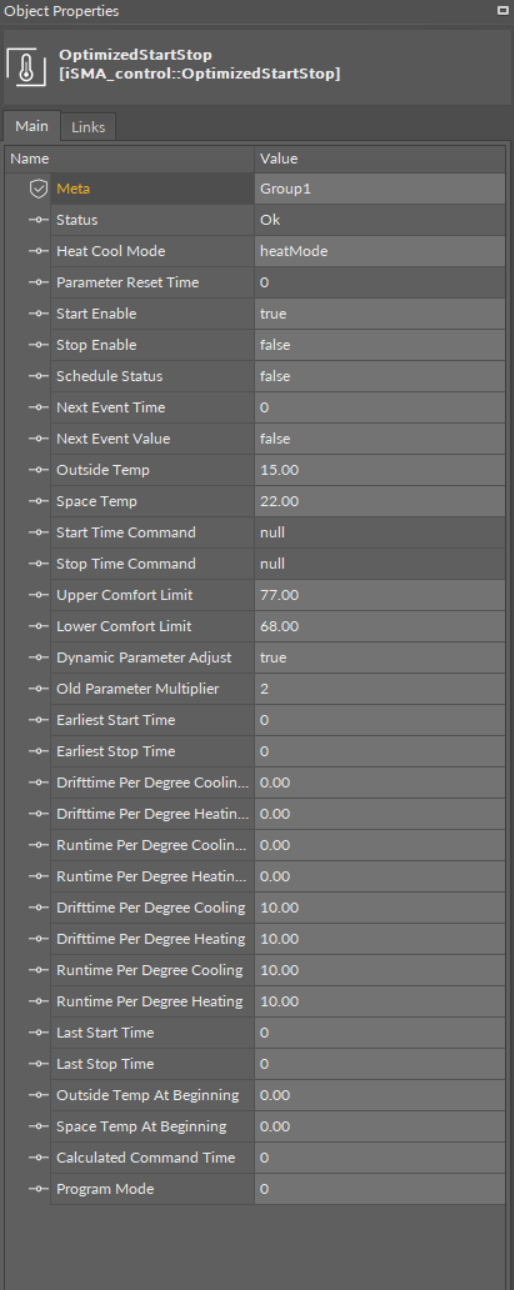

The OptimizedStartStop component allows using Start Time Optimization and Stop Time Optimization for energy saving. This component uses a space temperature input and area characteristics to calculate an optimal amount of lead-time before a scheduled event. It can analyze area temperature changes and adjust the optimization parameters based on the actual temperature change rates after an optimized start or stop.

OptimizedStartStop component

Slots

The OptimizedStartStop component has the following slots:

-

Heat Cool Mode: (Boolean) allows enabling either the Heat mode or the Cool mode. The selected option applies only to optimized stop calculations, which means that optimized stop calculations are performed only for the selected mode. Optimized start calculations are performed for both heat and cool modes, regardless of this property value;

-

Parameter Reset Time: displays the time when any of the four runtime or drift time properties change to the User Defined values. The OSS component copies the user-defined drift time and runtime property values to the corresponding actual drift time and runtime property values;

-

Start Enable: allows to manually or automatically enable or disable the optimized start function;

-

Stop Enable: this property allows to manually or automatically enable or disable the optimized stop function;

-

Schedule Status: (Boolean) monitors and displays the status of the schedule that is linked to it;

-

Next Event Time: this property is linked to the schedule for the time of the next scheduled event;

-

Next Event Value: this property is linked to the schedule and reflects the value of the action for the next scheduled event;

-

Outside Temp: this property is linked to outside temperature and displays the value for information only;

-

Space Temp: this property is linked to a space temperature output and displays the temperature of the area affected by equipment associated with the OSS component;

-

Start Time Command: (Boolean) the output that if linked to the control algorithm invokes an equipment start command. For example, it can be linked to a prioritized input of a Boolean writable point - or directly to the equipment start control;

-

Stop Time Command: (Boolean) the output that if linked to the control invokes an equipment stop command. For example, it can be linked to a prioritized input of a Boolean writable - or directly to the equipment stop control;

-

Upper Comfort Limit: this property value is the Cooling mode target temperature.

-

Lower Comfort Limit: the Heating mode target temperature;

-

Dynamic Parameter Adjust: controls whether or not calculation parameters are programmatically adjusted after an execution. After the OSS component completes the start or stop control, if this property value is set to true, the component evaluates the actual recovery rate (degrees/hour) and automatically adjusts the Runtime and Drifttime properties values so that they are influenced by actual drift time and run time;

-

Old Parameter Multiplier: weighs the dynamic parameter adjustment calculation. The value that is specified in this field affects how much weight is assigned to the previous runtime property value when it is used in the dynamic parameter adjustment calculation. A larger value increases the weight given to the previous runtime and a smaller value decreases the weight;

-

Earliest Start Time: allows to specify a time before which no optimized start command may be issued. If this value is set earlier than the Calculated Command Time, the Calculated Command Time is adjusted to equal to this time;

-

Earliest Stop Time: allows to specify a time before which no stop command may be issued. If this value is set earlier than the Calculated Command Time, the Calculated Command Time is adjusted to equal to this time;

-

Drifttime Per Degree Cooling User Defined: allows to set a default value for calculating the rate of drift in a cooling mode. A value saved in this field is copied to the Drifttime Per Degree Cooling field;

-

Drifttime Per Degree Heating User Defined: allows to set a default value for calculating the rate of drift in a heating mode. A value saved in this field is copied to the Drifttime Per Degree Heating field;

-

Runtime Per Degree Cooling User Defined: allows to set a default value for calculating the runtime value in a cooling mode. A value saved in this field is copied to the Runtime Per Degree Cooling field;

-

Runtime Per Degree Heating User Defined: allows to set a default value for calculating the runtime value in a heating mode. A value saved in this field is copied to the Runtime Per Degree Heating field;

-

Drifttime Per Degree Cooling: displays the actual value that is used for calculating an optimized stop time when the equipment is in a cooling mode. This value is adjusted automatically if the Dynamic Parameter Adjust value is set to true;

-

Drifttime Per Degree Heating: displays the actual value that is used for calculating an optimized stop time when the equipment is in a heating mode. This value is adjusted automatically if the Dynamic Parameter Adjust value is set to true;

-

Runtime Per Degree Cooling: displays the actual value that is used for calculating an optimized start time when the equipment is in a cooling mode. This value is adjusted automatically if the Dynamic Parameter Adjust value is set to true;

-

Runtime Per Degree Heating: displays the actual value that is used for calculating an optimized start time when the equipment is in a heating mode. This value is adjusted automatically if the Dynamic Parameter Adjust value is set to true;

-

Last Start Time: the record of the last Start Time that was used for calculating an optimized start time. Since only one optimized start per day is allowed, this value does not display Start Times (restarts) that are subsequent to the initial Start Time for a day;

-

Last Stop Time: the record of the last Stop Time that was used for calculating an optimized stop time. Since multiple Optimized Stops are allowed in a day, this value changes to reflect the latest Optimized Stop time;

-

Outside Temp at Beginning: the record of what the outside air temperature was at the time of the last start or stop command. This is the temperature that was used in calculations of dynamic parameter adjustment;

-

Space Temp at Beginning: the record of what the space temperature was at the time of the last start or stop command. This is the temperature that was used in calculations of dynamic parameter adjustment;

-

Calculated Command Time: shows the calculated time for the next command. This could be a start or a stop command;

-

Program Mode: As a part of the logic that the OSS component uses, there are five program mode states. These states serve primarily in logic control; however, they may as well be informative to the system engineer. The Program Mode value displays the current heating or cooling state for the optimized start or stop. The following list describes the possible display values and meanings:0 ("No" Calculation): indicates that no calculation is being made;1 ("Start" Calculation): indicates that the optimized start calculation process is ongoing, but that an optimized start or stop is not yet in progress;2 ("Start" in Process): indicates that the optimized start has been initiated;3 ("Stop" Calculation): indicates that the optimized stop calculation process is ongoing. but that an optimized start or stop is not yet in progress;4 ("Stop" in Process): indicates that the optimized stop has been initiated.